Magnetic and hydraulic quick mould clamping system

The greatest advantage of magnetic mould clamping systems with steel mould holder lies in the fact that the customer does not need to make any changes to the mould. the magnetic clamping system allows moulds of any shape to be clamped. the clamping force is equal to or higher than the machine’s opening force, and this is what ensures safe clamping. hydraulic clamping systems, on the other hand, are applied in the event of high mould standardisation and automated mould change lines.

Integrated island for automated mould change

For the strategic planning of mould changing sequences while monitoring the stock available. Project development and supply of automated manufacturing cells with mould handling, preheating, post-cooling, and changing.

Six-axis and cartesian robot automation

• High-speed demoulding

• Bi-material injection moulding

• Mould decoration and labelling

• Insert loading

• Controlled environment injection moulding

• Bonding / sealing

• Quality control

• Packaging

Remote control of moulding lines

We provide strategic planning monitoring systems, such as stock management, customer order date, medium-term planning, and moulding department management. Scheduling with mould change, colour, and material sequence optimisation and monitoring of the injection moulding machines with graphical and numerical indicators for every single resource.

Simulations and investment analysis

The information obtained from the simulation becomes an asset for the company, as it increases its competitiveness while reducing costs and investment risks of the industrial projects. Therefore, simulations are vital to the company’s development and their benefits extend to multiple sectors, such as environmental protection and occupational safety. The goal is to supply the elements that allow the determination of the final cost of a product made using injection moulding systems and technologies. In particular, the economic return is essential to evaluate new investments and innovative technologies.

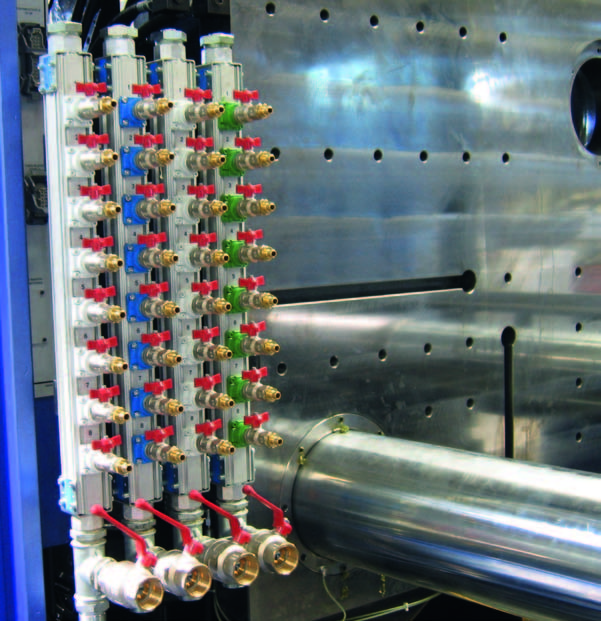

Cooling water connection and monitoring

Quality connection and monitoring systems for fluid mould coolants help achieve optimal moulding conditions in very short time. Multifitting systems for the simultaneous connection of electric and fluid lines, as well as clean-break, safety, and free passage couplings ensure high performance and long-term reliability.

Energy consumption monitoring

An effective control of energy costs requires the accurate measurement and monitoring of every energy source. We provide a complete high-performance system that allows even the remote measurement and viewing of the energy consumption. This application has a control panel and indicators, which provide an overview of the energy consumption. Any abnormal condition is reported immediately in order to take the right corrective action.